Steam enters a turbine operating at steady state, embarking on a journey that transforms thermal energy into mechanical power. This intricate process lies at the heart of modern energy generation and industrial applications, demanding a comprehensive exploration of its principles, components, and performance.

Delving into the realm of thermodynamics, we unravel the intricate dance of steam expansion, revealing the profound impact of pressure, temperature, and velocity on the turbine’s efficiency. By dissecting the turbine’s anatomy, we uncover the interplay between blades, rotors, and casing, each meticulously engineered to maximize energy conversion.

1. Introduction

A steam turbine is a mechanical device that converts the thermal energy of pressurized steam into mechanical energy. It operates on the principle of steady state, where the mass and energy flowing through the system remain constant over time.

2. Energy Conversion Process

In a steam turbine, high-pressure steam is directed through a series of nozzles, converting its thermal energy into kinetic energy. The high-velocity steam then impinges on the turbine blades, causing them to rotate. The rotation of the blades drives a shaft connected to a generator, converting the mechanical energy into electrical energy.

3. Turbine Components and Design: Steam Enters A Turbine Operating At Steady State

Main Components

- Blades: Fixed and moving blades form the passages through which steam flows, converting its energy into rotational motion.

- Rotors: Rotating shafts with blades attached, which convert the steam’s kinetic energy into mechanical energy.

- Casing: Encloses the rotating components, directing the steam flow and preventing leakage.

Design Considerations, Steam enters a turbine operating at steady state

Turbine design aims to maximize efficiency and minimize losses. Factors considered include blade shape, nozzle geometry, and the number of stages to optimize steam expansion and energy conversion.

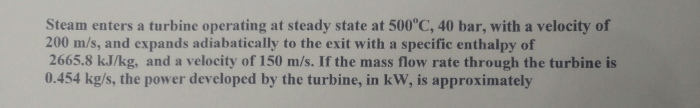

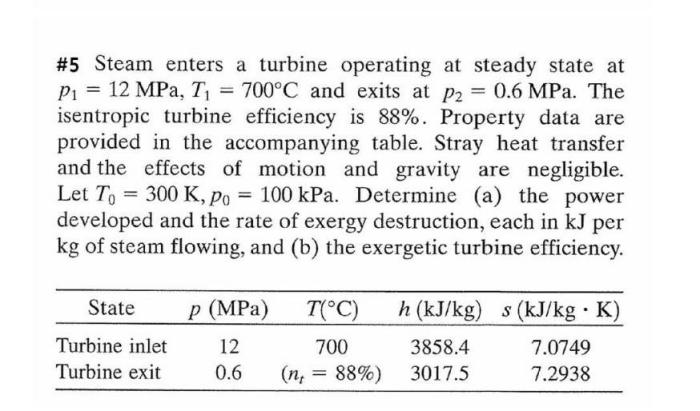

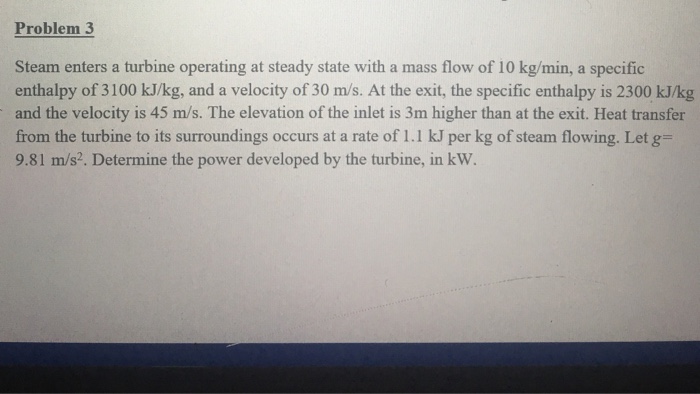

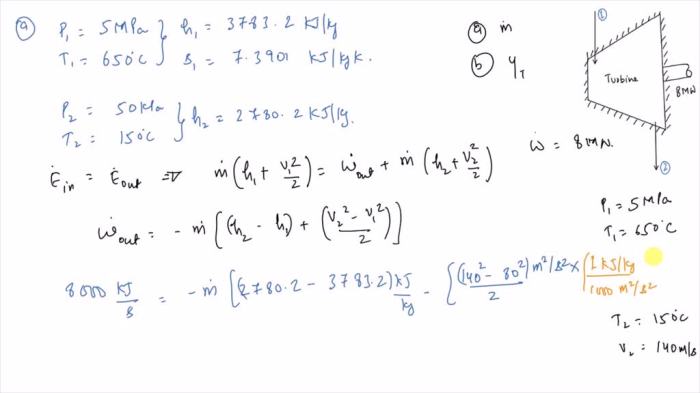

4. Thermodynamics of Steam Expansion

The expansion of steam in a turbine follows the principles of thermodynamics. The enthalpy drop of the steam as it expands through the nozzles and blades represents the work output of the turbine. The efficiency of the turbine is calculated based on the ratio of actual work output to the ideal work output.

5. Flow Dynamics and Fluid Mechanics

The flow patterns and fluid dynamics involved in steam expansion are crucial for turbine performance. The shape of the nozzles and the geometry of the blades influence the steam flow velocity, pressure, and direction, affecting the efficiency and stability of the turbine.

6. Performance Analysis and Optimization

Performance Measurement

Turbine performance is evaluated through parameters such as efficiency, specific steam consumption, and exhaust steam quality.

Optimization Strategies

- Blade design optimization: Enhancing blade shape and surface roughness to reduce flow losses.

- Nozzle geometry optimization: Adjusting nozzle shape to improve steam flow characteristics.

- Condenser optimization: Optimizing condenser design to maximize steam condensation and minimize exhaust steam pressure.

FAQ Insights

What is the principle behind a steam turbine?

A steam turbine operates on the principle of converting thermal energy stored in steam into mechanical energy. As high-pressure steam expands through the turbine’s blades, it imparts force on the blades, causing them to rotate.

What factors influence the efficiency of a steam turbine?

The efficiency of a steam turbine is primarily influenced by the steam’s pressure, temperature, and velocity, as well as the design of the turbine’s blades and nozzles.

What are the main applications of steam turbines?

Steam turbines find widespread use in power generation, industrial processes, and marine propulsion systems.